Press release -

Hitachi Rail and Turntide agreement opens way for battery trains across Britain

Hitachi Rail and Hyperdrive agreement opens way for battery trains across Britain

Hitachi Rail and Turntide Technologies (formerly Hyperdrive Innovation) have signed an exclusive agreement to develop battery packs to power zero-emission trains and create a battery hub in the North East.

The two North East manufacturers will now accelerate the creation of batteries that can be mass-produced to provide emission-free power for hundreds of battery trains across the UK.

With almost two-thirds (58%) of the UK’s 20,000 mile rail network not electrified and with the Government setting ambitious decarbonisation targets, Hitachi Rail analysis estimates the potential market for Turntide and Hitachi’s battery technology is over 400 trains.

This agreement is an important step towards manufacturing batteries at Turntide's facility in Sunderland, and then installing them just 20 miles away at Hitachi Rail’s train-building factory in Newton Aycliffe, County Durham.

Hitachi has identified its fleets of 275 trains as potential early recipients of the batteries for use in the UK, as well as installing them on new metro and intercity trains that will be needed in the coming years to replace ageing diesel fleets.

Battery trains produce no greenhouse gases, air pollution and are a far quieter, offering passengers cleaner air in stations, less noise disruption and a carbon-free way to travel. Installing batteries on to existing fleets can also extend their range and allow passengers to reach stations on non-electrified branch lines without having to change train.

A widespread adoption of battery train technology could be a major boost for industry in the UK, creating a market for Turntide to increase its manufacturing capability up to 30,000 battery packs per year and double the number of jobs at its Sunderland factory.

Development of the UK’s first independent battery pack manufacturing facility will drive costs down and for the first time offer domestic production of batteries for rail, automotive, construction and energy sectors.

This agreement is an example of a global company investing in one of its key markets and incubating local technology. It is a means of sharing of skills, resources and knowledge that will create battery packs that are best in class and help to position the North East as hub for battery technology – supporting the Government’s levelling-up agenda.

Andrew Barr, Group CEO, Hitachi Rail said: “Battery trains can play a vital role in improving the air we breathe, tackling climate change and providing modern, high performing rail service – all things we know passengers want to see.

“The partnership with Turntide creates shovel-ready opportunity for new battery trains to be ordered now. As well as new trains, this is also a window of opportunity to cut carbon and supercharge a green recovery in the North East and across the UK.”

Chris Pennison, CEO, Turntide Technologies said: “We’re delighted to bring our expertise and experience as a trusted electrification partner to a new industry, assisting an innovative organisation like Hitachi, as it modernises and decarbonises UK rail networks.

“Our partnership with Hitachi will secure major investment and jobs in the North East, reinforcing the UK’s battery supply chain and keeping the country on track to reach net-zero by 2050.”

“To date, only 42% of UK railways are electrified, with British trains using 469 million litres of diesel each year, emitting over 2.4 million tonnes CO2 annually. The partnership underpins the vision that the rail industry can be a major contributor to the UK government’s target of net zero emissions by 2050 and strengthens the case for home-grown innovation to be at the forefront of the UK’s clean growth strategy.”

Business and Industry Minister, Nadhim Zahawi said: “It’s fantastic to see two innovative companies joining forces to create good quality manufacturing jobs across the North East.

“An emission-free public transport system is vital if we’re to build a stronger, greener economic recovery that spreads prosperity and opportunity across the UK.”

Hitachi Rail battery train video can be viewed via – https://bit.ly/2C6zJg0

Hitachi Rail battery train images can be downloaded via – https://bit.ly/3irr74E

Notes to Editor

- Hitachi has extensive battery train experience across the world. In 2016, Hitachi introduced one of the world’s first regional battery trains in Japan. The Dencha currently carries passengers on two routes in Japan, with a wire-free range of 50km.

- In 2007, Hitachi Rail fitted a hybrid test train – known as a Class 43 HST – with batteries and ran over 100,000 km. The ‘Haybusa’ train produced no emissions out of stations and provided a 15% fuel saving.

- Cost and weight reduction of batteries continues to accelerate, while power density increases. The ease of integration on trains means the range and recharging of battery trains will only improve and meet the demands of different profiles of rail journeys.

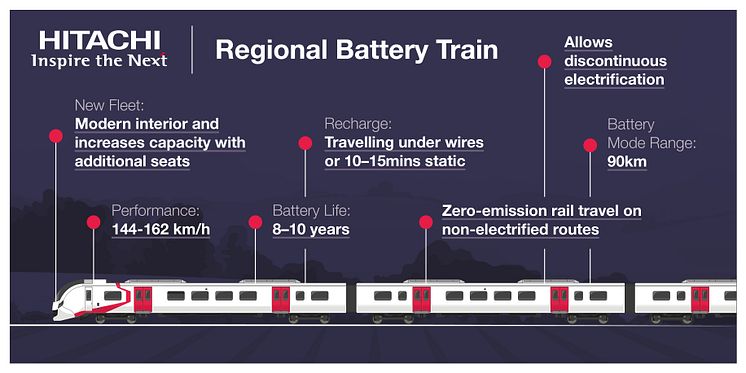

- Regional battery trains produce zero tailpipe emission and compatible with existing rail infrastructure so they can complement future electrification. At the moment, battery trains have approximately 50% lower lifecycle costs than hydrogen trains, making battery the cheapest and cleanest alternative zero-emission traction solution for trains.

- Under the terms of the Memorandum of Understanding (MoU), Hitachi Rail and Hyperdrive have agreed to jointly develop a battery pack that can be installed and power a battery train. The MoU also acts a roadmap to a manufacturing agreement that would cover future orders for battery trains.

- Hyperdrive Innovation has been the successful recipient of Advanced Propulsion Centre (APC) and Innovate UK funding. In 2016 Hyperdrive completed a £19m High Energy Density Battery (HEDB) Project in collaboration with Nissan and the APC.

Related links

Topics

Categories

About Hitachi Rail: Hitachi Rail is a fully integrated, global provider of rail solutions across rolling stock, signalling, service & maintenance, digital technology and turnkey solutions. With a presence in 38 countries across three continents and over 12,000 employees, our mission is to contribute to society through the continuous development of superior rail transport solutions. We are proud of our global achievements, from our world famous ‘bullet trains’, to our signalling solutions and turnkey projects, state-ofthe-art traffic management and digital solutions. Drawing on the wider Hitachi Group’s market-leading technology and research-and-development capabilities, we strive for industry leading innovations and solutions that can deliver value for customers and sustainable railway systems that benefit wider society. For information about Hitachi Rail, visit www.hitachirail.com.

About Hyperdrive Innovation: Founded in 2012, Hyperdrive Innovation designs and manufactures lithium-ion battery systems for powering off-highway and material handling vehicles as well as stationary and portable energy storage systems. Customers include JCB, Northern Powergrid and the world’s largest online grocery retailer.

Based in Sunderland, UK, where it employs more than 40 people, Hyperdrive has secured a global Supply Agreement to incorporate automotive quality lithium-ion cells into its high-performance battery systems.

Hyperdrive has been named in the top 40 of the Sunday Times Hiscox Tech Track 100 list as one of the fastest growing British tech firms. The company has also received numerous awards in recognition for its technology including the Automotive Award at Insider Media’s Made in the UK Awards 2019 and shortlisted for Innovation of the Year in the National Technology Awards.

In July 2019 Hyperdrive opened HYVE, the UK’s leading independent battery pack manufacturing facility, which can produce up to 30,000 packs per year. The expansion means that Hyperdrive has the largest dedicated battery manufacturing facility in the UK, outside major OEMs.